- Description

- Specification

- Features

- Additional Description

Description

Air showers quickly and effectively remove particulate that would otherwise be carried into the clean room, high air-flow volume combined with high nozzle velocity provide the power and force necessary for optimal operation.

Whether the goal is high semiconductor yields or a flawless paint finish, controlled environments are integral to manufacturing processes. Air showers are vital to maintaining the clean environment; they help protect operations from the constant threat of air particulate contamination. Semiconductor, medical device, bio-tech, microelectronic, optics, pharmaceutical, aerospace, Nano technology, and automotive industries require contaminant-free environments and use air showers as part of their operations.

Air showers are self-contained air recirculating systems installed at entrances to cloakrooms and other controlled environments. Because people and products are the main sources of cloakroom contamination, these clean room entry systems quickly and efficiently remove particulate contaminants from workers or products before they enter a clean space.

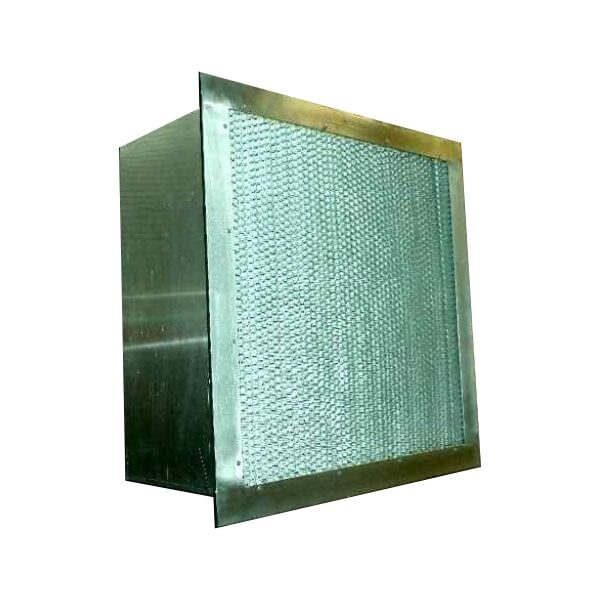

Air showers blow high-velocity jets of HEPA filtered air to remove loose particles from people and products before they enter a clean room. This decontamination process means cleaner air enters the clean room, reducing product defects and increasing production yields.

Additional advantages include longer-lasting clean room HEPA (high efficiency particulate air) Filters because contaminant loads are lower. Without the pre-cleaning Air showers provide, the main clean room air filtration system would absorb the entire contamination load, which increases energy consumption and maintenance costs.

Specification

Features

Options

Additional Description

- Description

- Specification

- Features

- Additional Description

Description

Air showers quickly and effectively remove particulate that would otherwise be carried into the clean room, high air-flow volume combined with high nozzle velocity provide the power and force necessary for optimal operation.

Whether the goal is high semiconductor yields or a flawless paint finish, controlled environments are integral to manufacturing processes. Air showers are vital to maintaining the clean environment; they help protect operations from the constant threat of air particulate contamination. Semiconductor, medical device, bio-tech, microelectronic, optics, pharmaceutical, aerospace, Nano technology, and automotive industries require contaminant-free environments and use air showers as part of their operations.

Air showers are self-contained air recirculating systems installed at entrances to cloakrooms and other controlled environments. Because people and products are the main sources of cloakroom contamination, these clean room entry systems quickly and efficiently remove particulate contaminants from workers or products before they enter a clean space.

Air showers blow high-velocity jets of HEPA filtered air to remove loose particles from people and products before they enter a clean room. This decontamination process means cleaner air enters the clean room, reducing product defects and increasing production yields.

Additional advantages include longer-lasting clean room HEPA (high efficiency particulate air) Filters because contaminant loads are lower. Without the pre-cleaning Air showers provide, the main clean room air filtration system would absorb the entire contamination load, which increases energy consumption and maintenance costs.