Description

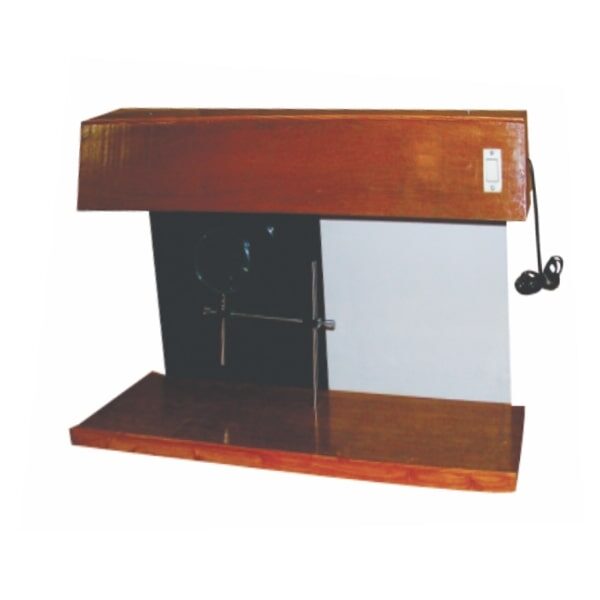

LAMBA UDYOG Automatic Tissue Processor is designed to prevent a solution to the rapid processing of tissue in Histology Laboratories . MPTP removes all the water from a tissue sample and replace it with paraffin wax with optimum speed to curtail damage to the tissues caused by dehydration and shrinkage.

Description

Operated by feather touch keyboard with digital display. Display shows : Real time, Date, month and year. Wax bath temperature : set temperature and attain temperature. Station no. is display in which tissue basket is running. Station time and lapse time shown on display.

SALIENT FEATURES Ÿ Empower to do most potentially hazardorous procedures on just a click. Ÿ System is prudent and well guarded. Ÿ Des ign i s s tout and proposes unswerving performance on smallest space.

FEATURES Ÿ Safety device for Tissue in case wax not melted the basket stop at the station 10th – 11th till the temperature is not attained. Ÿ Trouble free and maintenance free. Ÿ Heavy gauge used in fabrication of body. Ÿ Wax bath stainless steel inner outer with Teflon coated wire used in heater with best quality heating wire with thermal cut out of 75°C. Ÿ External body powder coated to avoid chipping and anti rusting chemical used all moving parts moving on Ball bearing oil sealed. Ÿ Not much maintenance required. Ÿ Main motor used Korean Geared motor to avoid vibration and sound. Ÿ In case of emergency side lifting handle provided to take out Tissue basket in case of Electricity failure. Ÿ Tissue basket capacity of 100 tissue cassette per Basket. Ÿ The instrument microprocessor controlled with adequate memory to save and retrieve at least 6 user selectable programs. Ÿ Rotary head have a lock out facility at the end of run to prevent basket moving from station 12 to station 1. Ÿ Have 10 stations with organic solvent resistant lipless beakers of 2 litre capacity. Ÿ Have a minimum of two temperature controller wax baths of 2 litre capacity. Ÿ Wax bath have user definable temperature range of at least 50 – 65 degree with a high temp cut off at 75°C +- 5°C. Ÿ Have individual programmable timing sequence for each station from 1 min to 6 hrs in increments of 1 min and programmable delay start time of up to 99 hrs. Ÿ Retain cycle information in case of power failure to continue processing on restoration of power. Ÿ The basket automatically be lowered into the nearest station in case of power failure during transfer of tissue basket from one station to next. Ÿ In case of power disruption during a cycle , then an error msg indicating the station in which there was power failure and the extra immersion time spend by the basket in the station will be flashed.

Description

LAMBA UDYOG Automatic Tissue Processor is designed to prevent a solution to the rapid processing of tissue in Histology Laboratories . MPTP removes all the water from a tissue sample and replace it with paraffin wax with optimum speed to curtail damage to the tissues caused by dehydration and shrinkage.

Description

Operated by feather touch keyboard with digital display. Display shows : Real time, Date, month and year. Wax bath temperature : set temperature and attain temperature. Station no. is display in which tissue basket is running. Station time and lapse time shown on display.

SALIENT FEATURES Ÿ Empower to do most potentially hazardorous procedures on just a click. Ÿ System is prudent and well guarded. Ÿ Des ign i s s tout and proposes unswerving performance on smallest space.

FEATURES Ÿ Safety device for Tissue in case wax not melted the basket stop at the station 10th – 11th till the temperature is not attained. Ÿ Trouble free and maintenance free. Ÿ Heavy gauge used in fabrication of body. Ÿ Wax bath stainless steel inner outer with Teflon coated wire used in heater with best quality heating wire with thermal cut out of 75°C. Ÿ External body powder coated to avoid chipping and anti rusting chemical used all moving parts moving on Ball bearing oil sealed. Ÿ Not much maintenance required. Ÿ Main motor used Korean Geared motor to avoid vibration and sound. Ÿ In case of emergency side lifting handle provided to take out Tissue basket in case of Electricity failure. Ÿ Tissue basket capacity of 100 tissue cassette per Basket. Ÿ The instrument microprocessor controlled with adequate memory to save and retrieve at least 6 user selectable programs. Ÿ Rotary head have a lock out facility at the end of run to prevent basket moving from station 12 to station 1. Ÿ Have 10 stations with organic solvent resistant lipless beakers of 2 litre capacity. Ÿ Have a minimum of two temperature controller wax baths of 2 litre capacity. Ÿ Wax bath have user definable temperature range of at least 50 – 65 degree with a high temp cut off at 75°C +- 5°C. Ÿ Have individual programmable timing sequence for each station from 1 min to 6 hrs in increments of 1 min and programmable delay start time of up to 99 hrs. Ÿ Retain cycle information in case of power failure to continue processing on restoration of power. Ÿ The basket automatically be lowered into the nearest station in case of power failure during transfer of tissue basket from one station to next. Ÿ In case of power disruption during a cycle , then an error msg indicating the station in which there was power failure and the extra immersion time spend by the basket in the station will be flashed.